Acoustic Voxels

Creator: Dingzeyu Li

Link: http://www.cs.columbia.edu/cg/lego/

Description:

Acoustic filters have a wide range of applications, yet customizing them with desired properties is difficult. Motivated by recent progress in additive manufacturing that allows for fast prototyping of complex shapes, we present a computational approach that automates the design of acoustic filters with complex geometries. In our approach, we construct an acoustic filter comprised of a set of parameterized shape primitives, whose transmission matrices can be precomputed. Using an efficient method of simulating the transmission matrix of an assembly built from these underlying primitives, our method is able to optimize both the arrangement and the parameters of the acoustic shape primitives in order to satisfy target acoustic properties of the filter. We validate our results against industrial laboratory measurements and high-quality off-line simulations. We demonstrate that our method enables a wide range of applications including muffler design, musical wind instrument prototyping, and encoding imperceptible acoustic information into everyday objects.

Photos:

Copper Rose

Creator: Alyssa Posecion

Link:

Description:

This project uses a large variety of tools at the MakerSpace including: aviation snips, the drill press, the soldering station, the mini-blow torch, and jewelry files. Originally intended as a present, each of the copper rose petals were cut out by hand and hammered out individually to get the final shape shown here.

Photos:

Hoverboard Replica

Creator: Justin Bui

Link: https://www.behance.net/gallery/42276669/The-Hoverboard

Description:

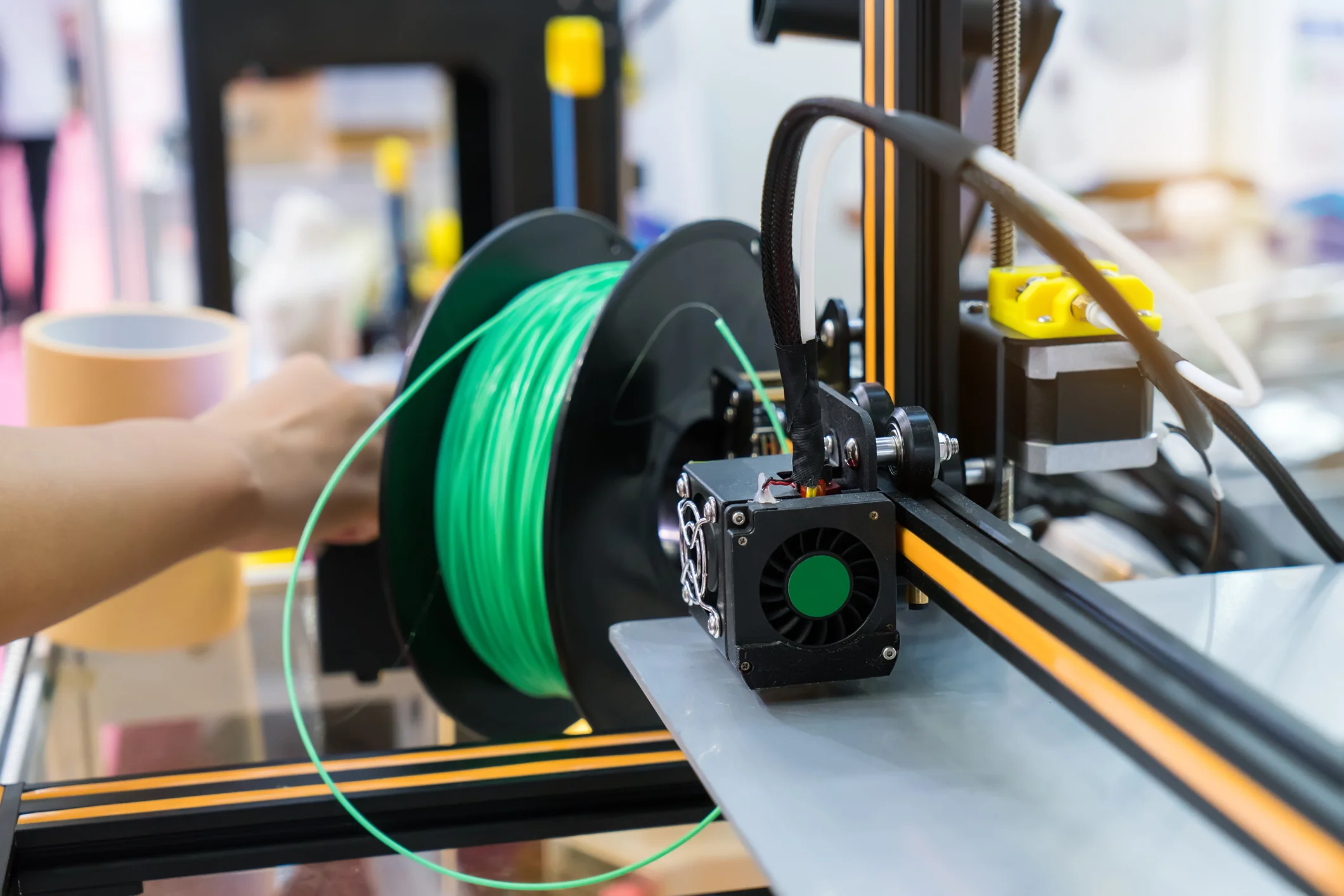

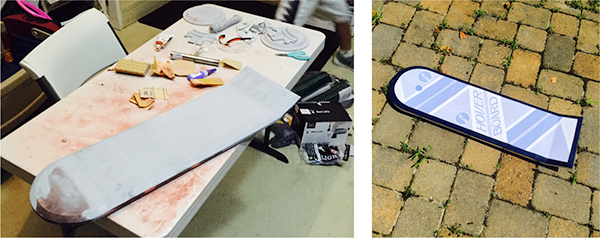

This is a Columbia colored 1:1 Scale Prop Replica of Marty's Hoverboard from Back to the Future Part 2. Every part on this hoverboard was designed in Autodesk Inventor and then 3D printed on the 3D printers in the Makerspace in PLA with the exception of the back bracket and the battery pack which were printed in grey resin.

The body of the board was printed in 6 pieces and then glued together. The seams were filled with Bondo spot glazing putty. Afterwards, the entire board, and all other PLA parts were sanded down to a 220 grit filled with filler primer and then wet sanded down to a 600 grit. A coat of blue spraypaint was applied and protected with a coat of a clear enamel. Finally, the decals were custom printed on Cricut Inkjet Vinyl and then applied to the board.

Photos:

Wooden Ring

Creator: Alyssa Posecion

Link:

Description:

These were created from scrap wood in the MakerSpace by drilling an initial hole with the drill press then using a dremel for a rough cut. Afterwards, the inside hole and outer shape were filed down by hand using a variety of different wood files. Here, the rings are drying after being dipped in a sealant.

Photos:

Laser Cut Sundial

Creator: Alyssa Posecion

Link: https://www.facebook.com/ColumbiaMakerSpace/posts/1861757440732315

Description:

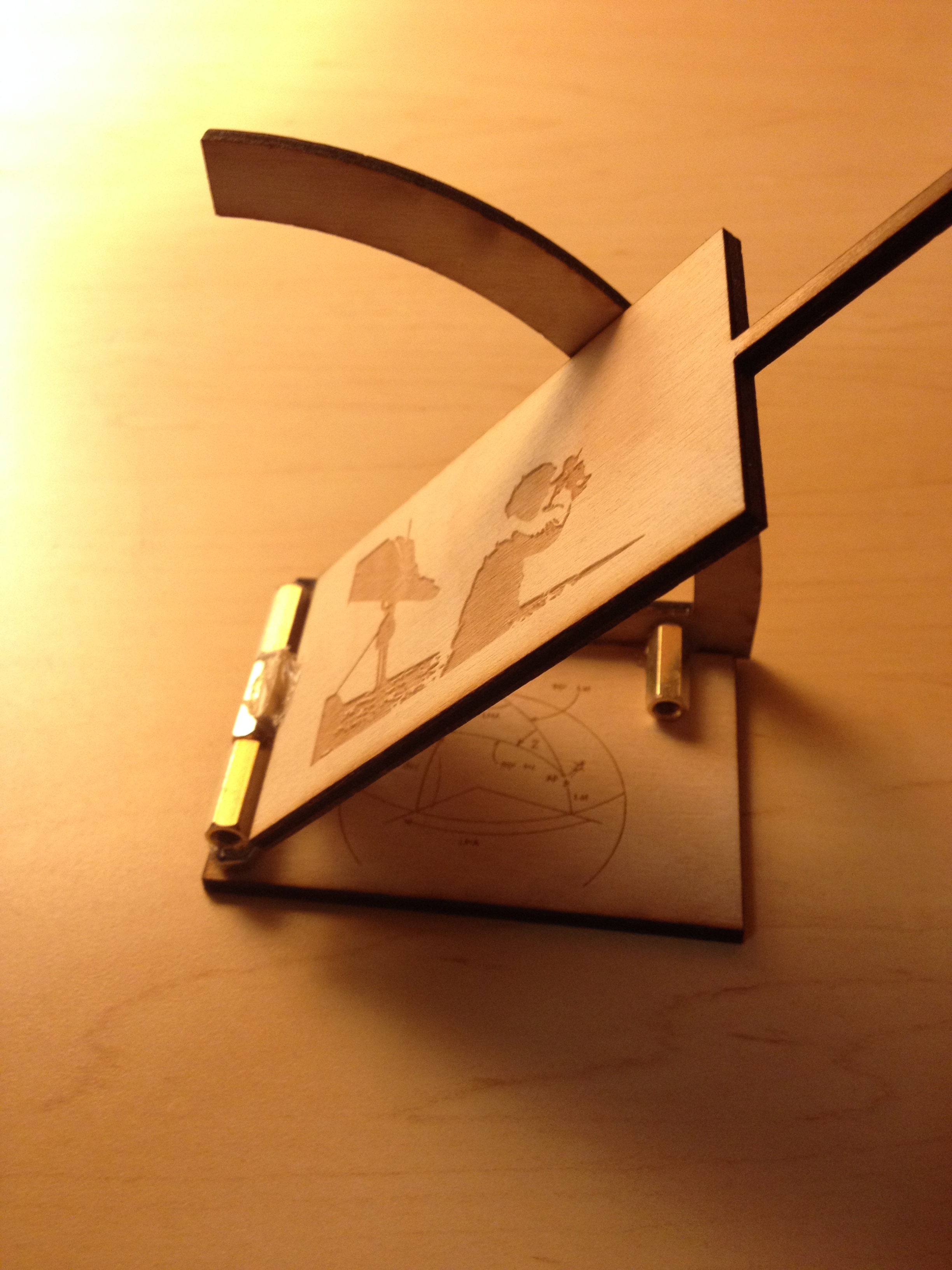

I previously used the laser-cutter to make a flat sundial. I needed a simple rising platform to calibrate the sundial to our latitude, in order to make it read accurate time. The platform swings through a 90 degree scale to do this. A little hot glue and the laser-cutter goes a long way!

Photos:

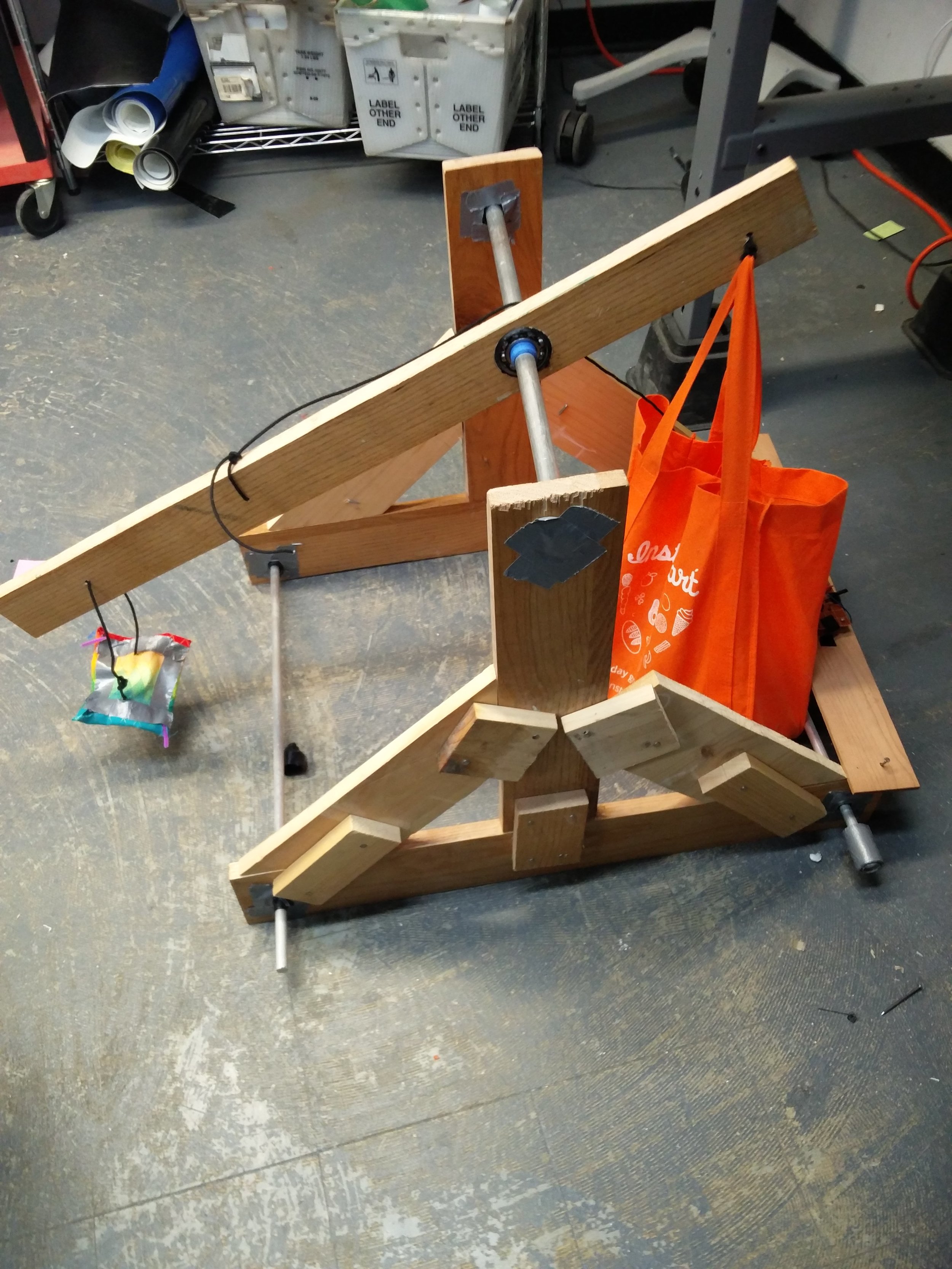

Trebuchet

Creator: Yonah Elorza

Link:

Description:

Photos:

T-Shirt Shooting Robot

Creator: Neil Chen

Link:

Description:

Built in the Columbia Makerspace off a $1000 Columbia Engineering grant, the T-Shirt Shooting Robot is a smartphone-operated, 100-pound robot that shoots t-shirts into crowds.

The T-Shirt Shooting Robot is packed with plenty of features, including:

- Automatically revolving shooter, to fire up to six shirts at a time

- OpenCV-powered computer vision to recognize and move towards human faces

- Custom mobile interface and Flask webserver, to communicate remotely with a human operator

- Adjustable shooter angle via a custom linear actuator

- Lasercut and 3D-printed construction, thanks to the Columbia MakerSpace

Photos: